Customise

Your

Packaging

Your

Packaging

Create impactful packaging, designed for your product.

Developed specifically to make your product standout against your competitors.

Create distinctive designs, shapes and finishes that reflect your brand.

Add new dimensions to your packaging with additional enhancements & features.

Keeps your product safe to ensure it arrives in the same condition as when it was packed.

Take a look at our customisation options below.

Transform our range of ready-to-fill packaging and add a unique feel that represents your brand with our label printing service.

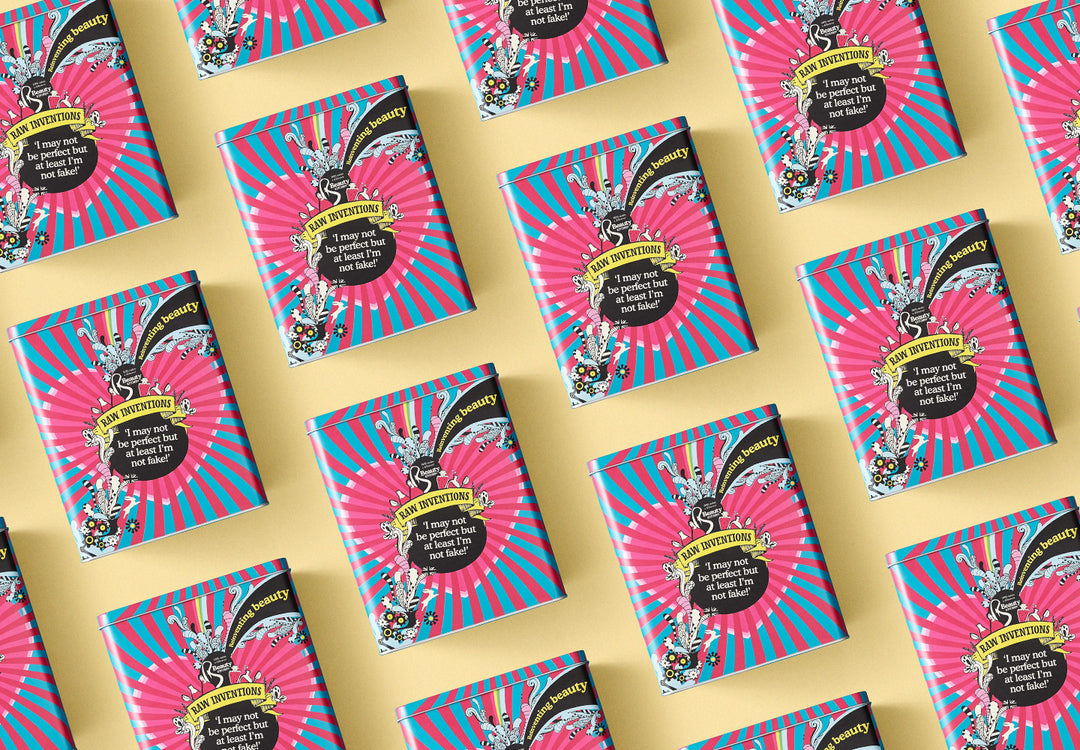

Supercharge your product with bespoke packaging that's bright, bold with edge-to-edge print.

Unbox sustainable luxury: Customisable cardboard packaging that elevates your brand and product to new levels.

Unleash your creativity and explore sustainable packaging designed to fit your product beautifully.

Looking to change up your packaging? We know that bespoke packaging can be expensive to develop, from new tooling to creating your first prototype.

At Tinware Direct, we have one of the largest tool collections available and we also offer free reproduction on all new products. So, whether you're looking to develop a new product or if you just want to swap to a more sustainable packaging solution, we're likely to have a tool available that will save you money and get your product to market quicker.

Our Team is here to help and can get you started on creating stunning packaging that connects your product to your customers. Get in touch today.