Tinplate & Aluminium Sustainability

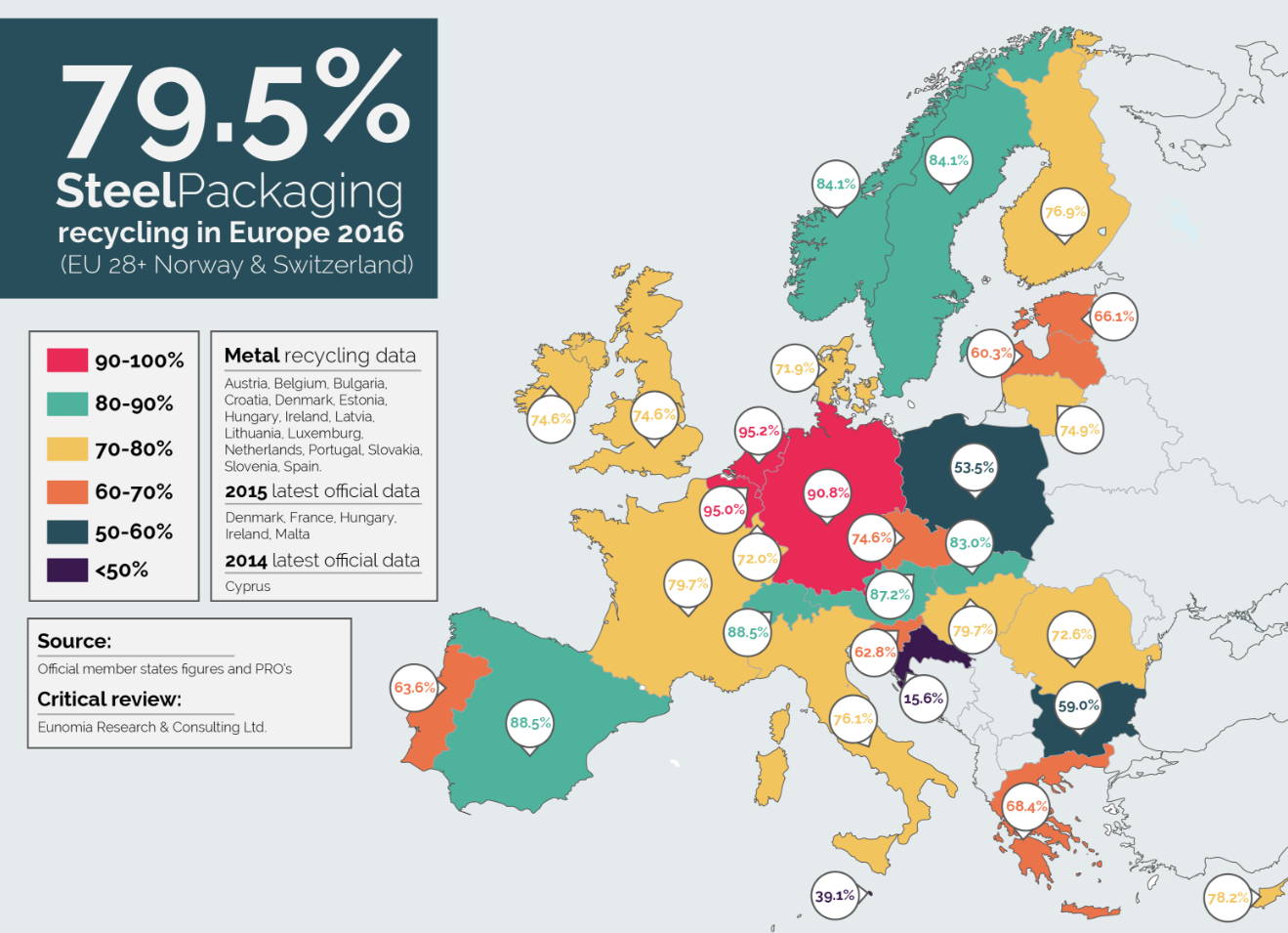

Manufacturing and packaging go hand in hand with sustainability. Tinplate and aluminium containers are both eco friendly and can be recycled. A latest report from APEAL¹ showed that steel packaging in Europe has reached a new high of 79.5% with an increase of 2% on 2015 data, steel for packaging’s recycling rate is pulling ever further away from that of other packaging materials.

The latest figures confirm steel as Europe’s most recycled packaging material for the 12th consecutive year. So, what makes Tinplate and Aluminium such a sustainable material?

Aluminium Sustainability

Unlike plastic, which degrades over time, aluminium can be melted down and reused over and over indefinitely, whether it is used for cans or other formats. Due to its lightweight properties, it can be converted into huge thin sheets that are easy to manipulate into any shapes imaginable.

To visualise why aluminium is so efficient, think of a giant sheet of aluminium weighing 9 metric tons but is as thin as construction paper. Such a roll can generate up to 3 million cans. Using a printer, the aluminium sheet feeds into a press that punches any shape required, any excess sheets are simply sent back and recycled into new rolls.

From an economic perspective, the recycle value per ton of aluminium is over three times greater than other materials such as plastic and glass. In 2014 the recycling rate for aluminium cans was 56.7% and this figure has been growing year on year. Fast forward to 2017 and the recycling rate for aluminium cans is at 72% meanwhile the recycling rates of glass and plastic bottles is around 35%. Around 70% of aluminium can content comes from recycled material on average, compared with the EPA's estimate that only 23% of glass bottles and 3% of plastic bottles are comprised of recycled material.

Tinplate Sustainability

Tinplating, which involves coating iron or steel with tin, used to be more common for manufacturing kitchenware like pots and pans. It is now mostly used for making tin cans due to the following factors:

- low toxicity

- corrosion resistant

- prevents rust

- production efficiency

- easy to recycle

As far as environmental impact, the recycle rate of tinplate has grown exponentially in recent decades. According to a report from the Association of European Producers of Steel for Packaging (APEAL), the recycle rate of tinplate increased from 25% in 1991 to 74% in 2012. Tinplate can be recycled multiple times without any loss in its protective properties.

Future of Sustainable Packaging

Sustainable packaging will continue to grow, as consumers are becoming increasingly more aware of environmental safety with plastic packaging receiving such bad press at the moment. Since packaging represents the first experience consumers often have with products, it's important for companies to take this transition to green thinking seriously. Regardless of how the product is made or what it contains, eco-friendly packaging sets the tone for a brand that people can trust for taking the initiative on helping protect the planet. In that sense, not only does eco-friendly packaging help build loyalty, it provides a competitive edge. It can help sway consumer purchasing decisions when price and quality are equal with competitors.

Source: https://www.apeal.org/news/steel-packaging-recycling-in-europe-reaches-795

At Tinware Direct, we are committed to helping the environment, so whether you’re a business or consumer, our recyclable metal packaging is the perfect alternative to plastic packaging.