Discover the Benefits of Our Aluminium and Tin Packaging

Check out our wide range of aluminium and tinplate packaging products. They’re great for food, cosmetics, sweets, candles, and more. Every tin we sell meets high-quality standards, and we always strive to exceed your expectations.

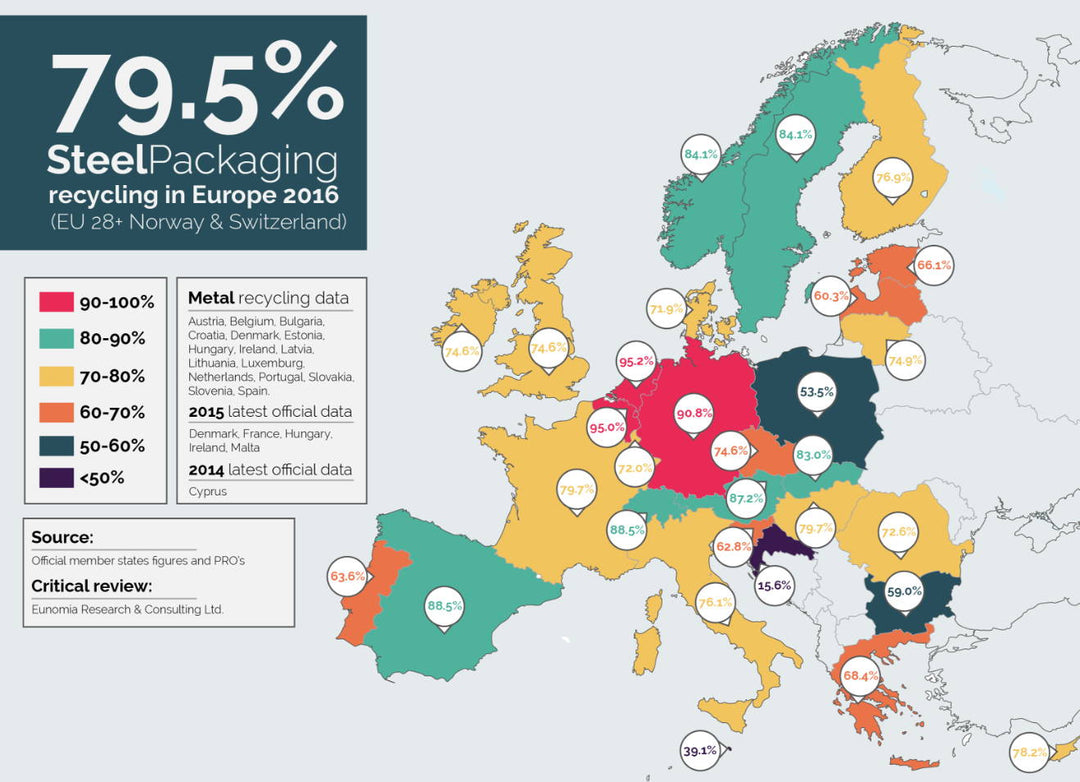

Choose from unique metal containers, like our innovative Pressitins and heart-shaped tins. These designs not only catch the eye but also offer practical benefits. Our metal packaging is made with at least 65% recycled material, and many products use over 70%. Metal is durable and can be recycled endlessly, making these containers vital for a circular economy and a greener future.

If you can’t find the perfect tin for your product, explore our bespoke tin service. Tinware Direct is one of the UK's most trusted tin packaging suppliers. We can help you create and customise the ideal metal packaging for your brand.